eddy current tester for hardness|eddy current testing in aerospace : supermarket Digital eddy current test instrument for one-channel nondestructive testing of metal components, mass-produced parts, and semi-finished products . Rafaela Nery (@rafaneryoficial) no TikTok |1.7M curtidas.281.8K seguidores.@rafaelanerylucca 19y Pesquisa rafaelanery.com no Google e seja .

{plog:ftitle_list}

Dass-173 Slutty Nh With Aizawa Sara. 23:31. 88 %. pretty trans sweetie with sexy feet legs strokes her cock on cam. pretty trans sweetie with sexy feet legs strokes her cock on cam. 21:45. 95 %. high heels redhaired russian shemale goddess masturbates with a .

who does eddy current testing

Eddy current testing is a useful method for identifying and evaluating flaws during inspections, including: Surface and near-surface cracks; Corrosion detection; Material thickness measurement; Conductivity testing; Top . In eddy current testing, a current is introduced to the material. Changes in the current based on the material provide valuable workpiece information such as flaws and surface cracks. Eddy current testing can also .Digital eddy current test instrument for one-channel nondestructive testing of metal components, mass-produced parts, and semi-finished products .Eddy current testing is one of several non-destructive testing methods that uses the electromagnetism principle for flaw detection in conductive materials. A specially designed coil energised with an alternating-current is placed in .

Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. With eddy current, analysts don’t have to worry about destructive testing measures that waste materials. A hardness testing campaign should include sophisticated equipment that roots out abnormalities on a mass level. Hardness Sorting is a specialized application of Eddy Current Testing that deals with distinguishing materials based on hardness levels. This technique plays a vital role in industries such as automotive, aerospace, and manufacturing, where material hardness directly impacts the performance and lifespan of components.Turnkey systems can be built from one source to your application using a complete line of eddy current testers, instruments, and systems for non destructive testing of metal components. . Hardness Testing Machines; Vision Systems; Industries. Aerospace NDT Automotive NDT Nuclear NDT. Resources. Company. 980 Salem Pkwy, Salem, OH 44460. 330 .

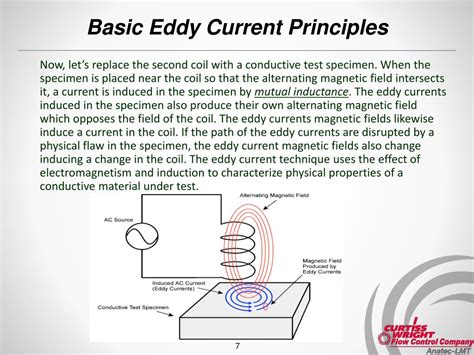

Digital eddy current test instrument for nondestructive testing of mass-produced parts, metal components, and semi-finished products for material properties such as hardness, case depth, structure, tensile strength, heat treatment, or alloy using .4.1.6.2 Effect of Permeability on Eddy Currents.Eddy current testing of ferromagnetic parts is usually limited to . 4.1.6.7 Heat Treat Condition or Hardness.Heat treating (or age hardening) a metal changes its hardness and its electrical conductivity. Just as above, the aluminum alloys have been the most investigated for the hardness .Eddy Current Testing (ECT) is a non-destructive testing (NDT) technique used to detect and characterize surface and near-surface defects in conductive materials. It relies on the principle of electromagnetic induction. Aluminum alloys are heat treated to provide optimal material properties for use in a variety of applications. However, when exposed to abnormally high temperatures, an evaluation must be performed to determine if the aluminum component has been compromised. Nondestructive evaluation of aluminum alloys, by means of electrical conductivity and .

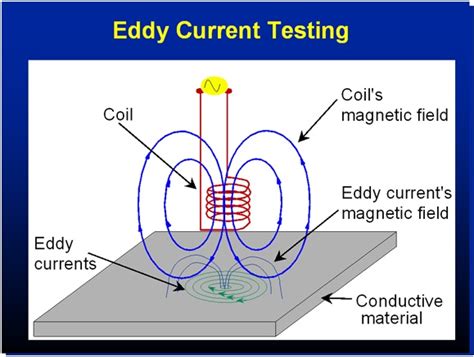

Eddy current testing is a non-destructive method for testing metal surfaces for defects such as longitudinal and transverse cracks. The type of testing performed, using comprehensive through-type coils or rotating probes, depends on the type of defect. . Typical test tasks include hardness checks, material differentiation and sorting. Find .An eddy current tester sends an alternating current through a coil which generates an oscillating magnetic field. When the probe is placed near the surface of a conductive metal, a circular flow of electrons, an eddy current, begins to move through the metal and generate its own magnetic field which interacts with the magnetic field created by .Eddy current testing uses electromagnetic induction to detect defects in both ferrous and non-ferrous materials by inducing an eddy current field in the specimen under test. A variety of inspections can be performed with eddy current testing and it is typically used for surface and near-surface flaw detection, metal and coating thickness .

Learn how eddy current non-destructive test systems integrate into production lines, provide quality assurance, & reduce scrap, warranty, and liability costs. . Ball Bearing Hardness Test Piston Ring Orientation Check High-Speed Thread .The eddy current method can be used for very different applications. In this video we would like to show how the FOERSTER DEFECTOMETER is used to sort differ.

Metaltest provides electrical conductivity testing for determining the electrical conductivity of nonmagnetic metals using the electromagnetic (eddy-current) method. This test is applicable to metals that have either a flat or slightly curved surface and includes metals with or without a thin nonconductive coating.

Get all the features you need in an eddy current tester, including multiple frequencies, accurate readings and logging, all from leading brands like AutoSIGMA. Contact: (913) 685-0675. Products. All Products . –+ Hardness .

Find here online price details of companies selling Eddy Current Tester. Get info of suppliers, manufacturers, exporters, traders of Eddy Current Tester for buying in India. IndiaMART. Get Best Price. Shopping . Hardness / Grade Mix .

Eddy current hardness testing. Testing materials or products for hardness is a common practice in many industries for ensuring that the items being tested can withstand normal wear and tear. Eddy current hardness testing is one of the . In order to develop a correlation between the eddy current and Rockwell hardness (HrB) test methods, two tests were conducted. 380 samples (38 sets of 10 samples) were tested with a Rockwell hardness tester and the eddy current test system. Improperly hardened specimens were included in the test batch.With the right eddy current testing devices, technicians can carry out successful hardness testing and validate that the hardness meets specific regulations. With the devices we recommend, technicians can rapidly find flaws and remove the faulty parts from the assembly line, enhancing safety and productive operations.The principle involves the generation of alternating current within a coil or conductor, engendering a dynamic magnetic field in its vicinity. When this energized coil approaches a conductive material, such as a metal component, it imparts within the material circulating electric currents – referred to as "eddy currents."

Eddy current is a non-destructive testing technique that uses a probe to induce small alternating current within the part that is being examined. Eddy current testing produces a rapid and easily used method of determining the conductivity of a part. A typical eddy current conductivity tester is shown in Figure 3. Reference standards are .

how eddy current testing works

We are the manufacturer & supplier of Eddy Current Tester, Materialography, Metallography including eddy current tester & Dimensional Equipment. 1038521826884939 . we can create customized machines such as hardness tester, microscopes and automatics cutting machines in our in-house lab. We have dedicated engineers and professional having rich .VARIMAC® VI EDDY CURRENT COMPARATOR Tests Hardness, Alloy, Dimensions and Physical Characteristics in Metal Test and sort fasteners, bearings and other cold formed pieces using 100% nondestructive testing.Check for hardness and correct grade in wire and bar.Test ferrous (magnetic) or nonferrous (non-magnetic) material.Use with MAC® Parts Gate for high .

Eddy Current Testing (ET) Hardness Testing (HT) Liquid Penetrant Testing (PT) Magnetic Particle Inspection (MPI) Radiography (RT) Ultrasonic Testing (UT) . What is Eddy Current Testing? Eddy current testing is an electromagnetic technique and can only be used on conductive materials. It’s applications range from crack detection, to the .In its most basic form — the single-element eddy current testing probe — a copper wire is excited with an alternating electrical current. This wire produces a magnetic field around itself in the direction ascertained by the right-hand rule. This magnetic field oscillates at the same frequency as the current running through the coil. Features. Advanced Eddy Current Technology: Our Eddy Current testing Machine Instruments utilize the latest in Eddy current testing technology to accurately identify and sort materials based on their hardness and material properties. User-Friendly Interface: Our Eddy Current testing Machine Equipment is designed with the end user in mind, featuring an .These videos demonstrate how eddy testing equipment serves to test valve cover thread, quick sort by hardness, test for cracks, roller bearing flaws, & more.

custom go better moisture meter

Resultado da Welcome Bonus. Terminated. Coral Casino: 100% up to £25 Table Games Welcome Bonus. Type Welcome Bonus. Bonus Value £25. Minimum Deposit £25. W.R. 40xb. Cashable Yes. Coral Casino bonus & promo codes (2024) Free spins, no deposit and welcome bonus Claim Coral Casino bonuses.

eddy current tester for hardness|eddy current testing in aerospace